OBJECTIVE

To provide

guidelines to minimize the risks associated with workplace noise exposure to

employees and to prevent noise induced hearing loss (NIHL). The company is committed to provide

employees with a safe and healthful working environment. This is optimally

accomplished by incorporating feasible safeguards into facilities and equipment

designs. When effective engineering controls are not feasible, or when they are

being initiated, administrative controls and/or personal protective equipment

will be utilized to prevent employee exposure to noise over regulated or

recommended levels.

SCOPE

Applicable to activities carried out within the

company premise.

RESPONSIBILITY

Management

The management shall:

-Ensure that noise control

measures are in place such that no employees are exposed to excessive noise.

-Where

50 or more persons employed are exposed or likely to be exposed to excessive

noise, a competent person (Noise Control Officer) should be

appointed to advise the management on the proper noise control measures.

-Ensure that the individuals

who advise on noise control are suitably qualified, whether in-house personnel

or service provider.

-Allocate appropriate

resources and, as far as it is reasonably practicable, implement the noise

control plan put up by the competent person.

-Ensure that the noise

control plan be reviewed at least once every three years or until such time

when the noise is reduced to an acceptable level and the

noise hazard is eliminated.

-Consider

the noise emission levels during the selection and procurement of new machines

since the selection of quieter machines at the initial stage can bring

about cost savings from the need to introduce noise control measures after

initial installation.

-Appoint a Hearing Conservation Program (HCP) Administrator to take

charge of the HCP.

The HCP administrator should be an individual who has keen interest

in the company’s HCP. He / She should possess good communication skills and

spend time at the production floor to interact with employees to discuss the

noise problems and associated prevention or solutions.

HCP Administrator

The HCP administrator should coordinate all aspects

of the program and possess knowledge on:

-individual elements of HCP

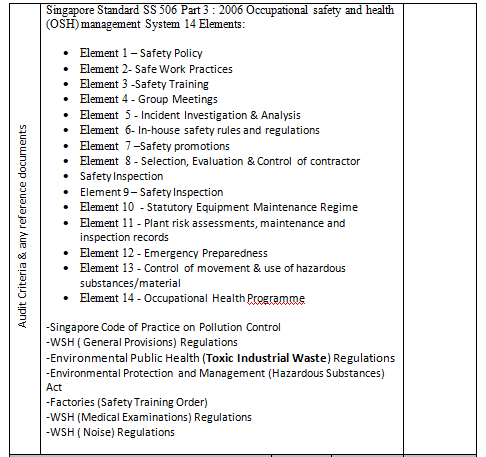

-relevant provisions of the Workplace Safety and

Health (WSH) Act, the Workplace Safety and Health (Noise) Regulations, and the WSH (Risk

Management) Regulations,

-effects of noise on hearing, and

-purpose of hearing protectors and audiometric

examinations

The EHS Officer / Manager shall be the HCP

Administrator. He / She shall:

-coordinate the HCP,

-monitor its progress,

-assess its performance,

-evaluate its effectiveness,

-review the HCP at regular intervals,

-ensure that the set objectives are met,

-arrange meetings or discussions to promote collaboration of

effort between management and team members, and-foster exchange of information between management and team members on the

progress of the program

Competent person for

noise monitoring:

A

competent person is an individual who is trained to conduct proper noise

monitoring. The person should work with the HCP administrator to ensure that

noise monitoring is conducted properly. The tasks of a competent person

include:

-Identifying work areas with

excessive noise i.e. areas where employees are exposed or likely to be exposed

to noise levels at or above 85 dB(A).

-Identifying individual

noise sources (e.g. equipment, machines, processes, operations and work

activities) which contribute to the excessive noise in the

work areas.

-Monitoring or assessing the

noise exposure levels of individual persons working in the work areas

identified to have excessive noise. Determine whether the

noise exposure levels are excessive, i.e., at or above an equivalent sound pressure level of 85 dB(A) over an

eight-hour period per day.

-Conducting noise monitoring

or measurements at regular intervals (at least once every three years) or

whenever there is any change in equipment, machinery,

processes, operations, controls or other conditions, which may result in excessive noise generation or emission.

Ensuring that

the instruments used for noise monitoring are calibrated at required intervals.

The accuracy of the instruments should be verified with an acoustic calibrator

immediately before and after every measurement.

In addition, the instrument used should be sent to the manufacturer or

its authorized agents for servicing and maintenance at intervals recommended by

the manufacturer.

Ensuring

that noise measurements performed are

representative of employee’s normal daily exposure to noise. To obtain

representative results, the following should be considered:

-ensure

adequate sampling of all work processes,

-ensure

adequate duration of sampling, and

-discuss

with employees to have a better understanding of the work environment and processes monitored to obtain a more representative measurement.

-Ensure

the appropriate selection of parameters, such as weighting network, meter’s

response, exchange rate, criterion levels and threshold levels for accurate

noise measurements. Normally an ‘A’ weighting network is used to measure the average noise levels while a ‘C’

weighting network is used to measure peak and impact / impulse noise.

The

following points should be noted during measurement:

.Measure

at a suitable distance from the noise source. The sound measuring instrument

should be held at arm’s length or using a remote microphone to avoid

reflections from the body.

.Keep

away from reflecting surfaces.

.Ensure

that there are no obstacles between the noise source and the instrument.

.Check

background noise level and make corrections if necessary.

.Use

a wind shield to protect the microphone.

-Prepare

a Noise Monitoring Report as described in the WSH (Noise) Regulations.

-Perform

a noise mapping of work areas with excessive noise, including a contour of 85

dB(A) around the noise source(s) on the noise map.

-Present

and explain the results of noise monitoring in a clear and understandable

format to the management and employees. Ensure that results of the

noise monitoring are communicated to all persons exposed to excessive noise not later than 14 days after preparation of

the report.

-Assist

management in implementing a job rotation schedule for the exposed employees if

engineering noise controls are not practicable.

-Assist

management in implementing a maintenance program for equipment and machinery to

minimise noise generation from friction, wear and tear,

or unbalanced parts of machines.

-Assist management in implementing a HCP which includes regular

noise monitoring, hearing protection and health education of persons exposed to

excessive noise.

Competent person for noise control:

A noise

control officer is an individual who is adequately trained and knowledgeable on

the details of noise control to provide the management with sound advice on the

proper noise control measures. He/ She should work with the HCP administrator

and the employees to ensure that the proposed noise control measures are

implemented. The tasks of a noise control officer include:

-Identifying

all possible noise sources.

-Evaluating

specific machinery or noise source for noise control, and determining the most

practical and effective methods of reducing the noise to meet

the desired criteria.

-Involving

the machine operators or production people on the selection of the noise

control measures which may interfere with their work; communicate

with them on the proper use of the noise control devices to ensure that the controls are kept in good condition.

.Developing

a comprehensive noise control plan with recommendations on engineering noise

controls where practicable. A sample template of the

noise control plan is in Appendix C.

-Working

closely with the management when putting up the noise control plan, especially

in recommending priorities and setting targets for noise control.

-Assisting

the management in implementing the noise control plan and evaluating the

effectiveness of noise control measures.

-Reviewing

and revising the noise control plan at least once every three years or whenever

there is a significant change in the work processes or machinery