Identification of Noise

Hazards

-Risk assessment shall be carried out as per QEHS-SP-12 Risk Management

-A site inspection shall be carried out by the RA team using the aid of Appendix A - Noise Hazard Identification Checklist for a quick qualitative assessment to identify noise hazards present in the workplace.

-When it is identified that noise hazards exist, noise monitoring shall be carried out.

Noise Monitoring

Where 10 or more persons are potentially exposed to excessive noise, a competent person (consultant) shall be engaged to conduct noise monitoring once every three years, or earlier when changes in conditions occur that may cause any employee to be exposed to excessive noise.

The EHS Officer / Manager may also recommend noise monitoring even if less than 10 persons may be potentially exposed to excessive noise.

Objectives of Noise

Monitoring

Noise monitoring shall be performed to achieve the following objectives:

.quantify the noise hazards;

.identify employees affected by the noise hazards for inclusion in the HCP

.classify employees’ noise exposures for prioritising noise control efforts and establishing hearing protection practices,

.evaluate specific noise sources for noise control purposes,

.evaluate the effectiveness of the measures taken to minimise noise exposure, and

.delineate hearing protection area

Methods of Noise Monitoring

The types of noise monitoring usually include:

Area surveys

A sound level meter is used to measure noise levels at work areas where noise hazards have been identified. The results of measurements are normally plotted in the form of a “noise map”, which clearly indicates areas with sound pressure levels above the permissible exposure limit of 85 dB(A).

Dosimetry

Noise dosimeters can be worn by employees to monitor personal noise exposure over the work shift. Some noise dosimeters are able to record a time history of an employee’s noise exposure for the measurement period. This allows identification of noise sources, which have a significant contribution to the employee’s noise exposure level. When performing a noise dosimetry, the following points should be considered:

-reflection of sound from the body may increase the noise level measured,

-the microphone should be attached as close as possible to the ear as inappropriate positioning of the microphone, such as at the lower part of the collar or pocket, may give rise to higher or lower readings, and

-more measurements may be required if monitoring over a single work shift is unable to give a representative sample.

Evaluation of Noise Risk

After the noise hazards have been identified, the risks associated with the hazards shall be evaluated to determine if it is acceptable or if control measures are needed.

The HOD in charge of processes / activities where noise hazards exist shall ensure that the result of the risk evaluation is communicated to all affected employees.

The HOD shall ensure that risk assessments must be communicated to the employees, and monitor the implementation of the follow-up actions.

Engineering surveys

Engineering surveys involve the use of octave band analyzers which provide information on the frequency composition of the noise being generated by a noise source. The results of measurement are used to assess options for the for the application of engineering noise controls

Noise Control Measures

After the noise hazards have been identified and evaluated, the next step of risk assessment involves the reduction of the noise risk to an acceptable level through the application of reasonably practicable controls.

The following principles of control shall be applied:

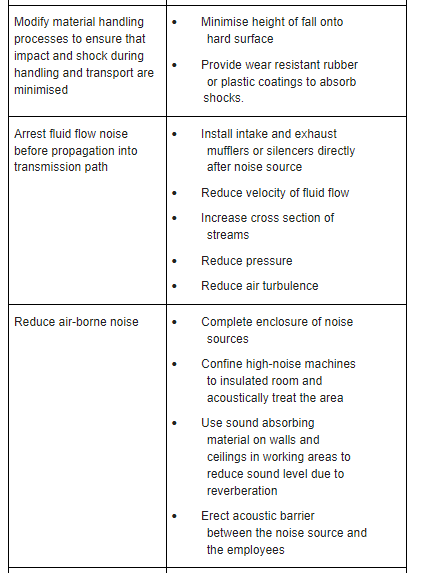

Noise control at the source.

Noise control at the source is an

engineering remedy. Vibration control or isolation, damping or lagging of

vibrating surfaces, proper balancing and maintenance of machinery can reduce

noise. Mufflers or silencers can control noise generated by turbulent fluid

flow.

Noise control along the path

The control of noise along the path of transmission involves the modification of the paths by which noise travels through the air to the employees. It can be achieved by complete or partial enclosure of the source, by placing an acoustical shield or barrier wall between the source and the receiver, or by increasing the distance between them. Sometimes, the installation of acoustical absorbing materials on ceilings or walls may result in significant reduction of noise

Noise control at the receiver

Noise control at the receiver can be achieved by the use of hearing protectors, by use of personal enclosure or by application of administrative controls such as job rotation.

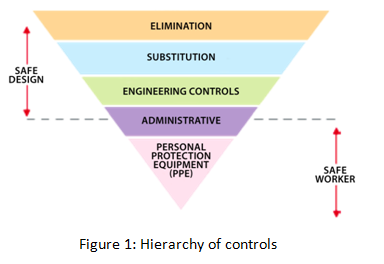

Hierarchy of Controls

The control of noise hazards can be accomplished through the following hierarchy of controls as shown in Figure 1 below

Substitution

Substitution involves replacing the hazard by one that presents a lower risk. For example, substitute noisy machinery/equipment with ones designed for operation at lower noise levels.

Engineering control

Engineering controls are physical means that limit the hazard.

These include structural changes to the work environment or work process

Administrative control

Administrative

control is any arrangement or procedure that limits the daily noise exposure of

employees by control of the work or production schedule. Examples of

administrative methods include:

.Shortening the length of time an employee is exposed to excessive noise by job rotation, and

.Scheduling machine operating times to reduce the number of employees exposed to noise.

Administrative methods do not reduce the noise level and therefore should not be used as a primary means of preventing hearing loss. However, administrative control can be considered when engineering methods are not practicable.

PPE

Appropriate, proper fitting individual hearing protectors should be considered as an interim solution to reduce the sound exposure of the employees before engineering and administrative noise controls can be administered or when the controls are not yet feasible. It can be used to provide added protection in addition to engineering and administrative controls.

Noise control measures

Once it has been ascertained through risk evaluation that the risk posed by the excessive noise in the workplace is unacceptable, a noise control measures shall be proposed in the risk assessment.

The proposed control measure, implementation person and due date for completion shall be recorded in the risk assessment form

The following should be taken into consideration when developing

noise control measures:

-Noise control measures for new and existing processes, machinery and equipment should be considered

-In the case of new processes, machinery and equipment, the noise control officer should, where possible, advise the management to:

.specify low noise output of the processes, machinery and equipment

as a condition of purchase alongside

production-

related specifications. .arrange the workplace layout to minimise noise exposure to the employees.

-In

the case of existing processes, machinery and equipment, the noise control

officer should advise the management to consider alternative ways of reduction

without generating excessive noise.

-If

elimination of the noisy process or machine is not practicable, the noise

control officer should advise the management to consider replacing the noisy

parts with quieter alternatives.

-If

elimination and substitution are not practicable, the use of engineering and

administrative controls should be considered.

-Hearing protectors must be provided to all persons exposed to

noise hazard during the interim period of noise control implementation and in

the absence of feasible engineering and administrative controls. The noise

control officer should advise the management to provide hearing protection

devices and ensure their correct use by the affected employees

The HOD-in-charge shall ensure regular monitoring of the proposed

noise control measure(s) to ensure timely completion.

After the noise control measures have been implemented, their

effectiveness should be evaluated through performing another round of risk

assessment .

No comments:

Post a Comment